EPA Regulations & Green Tech: 3-Month Plan for US Manufacturers

U.S. manufacturers must immediately implement a strategic 3-month action plan to navigate and comply with the latest EPA regulations concerning green technology adoption, ensuring operational continuity and competitive advantage.

Navigating the New EPA Regulations for Green Tech Adoption: A 3-Month Action Plan for U.S. Manufacturers is not just a strategic necessity; it’s an immediate imperative. As new environmental policies take effect, understanding and adapting quickly will define success in a rapidly evolving industrial landscape. What steps must manufacturers take now to ensure compliance and seize new opportunities?

Understanding the Latest EPA Directives

The U.S. Environmental Protection Agency (EPA) has recently rolled out a series of updated regulations aimed at accelerating green technology adoption across the manufacturing sector. These directives, effective as of [Current Date – e.g., October 26, 2023], emphasize reducing carbon footprints, improving waste management, and promoting sustainable production processes. Manufacturers are now faced with the urgent task of deciphering these complex rules and integrating them into their operational frameworks.

These new regulations are not merely incremental changes; they represent a significant shift towards a more environmentally conscious industrial economy. The EPA’s focus is clearly on measurable outcomes, pushing for innovations that lead to tangible reductions in pollution and resource consumption. This includes stricter limits on emissions, enhanced requirements for reporting, and incentives for adopting renewable energy sources and circular economy practices.

Key Regulatory Updates

Several critical updates have been identified as central to the new EPA framework. These include revised standards for air and water discharge, new guidelines for chemical usage, and expanded reporting mandates for greenhouse gas emissions. The agency is also providing updated guidance on best available control technologies (BACT) and encouraging the use of life cycle assessments (LCAs) for products.

- Emissions Standards: Tighter limits for volatile organic compounds (VOCs) and hazardous air pollutants (HAPs).

- Water Discharge: New requirements for industrial wastewater treatment and discharge permits.

- Chemical Management: Increased scrutiny on the use and disposal of per- and polyfluoroalkyl substances (PFAS).

- Reporting Mandates: Expanded scope and frequency for environmental data submissions.

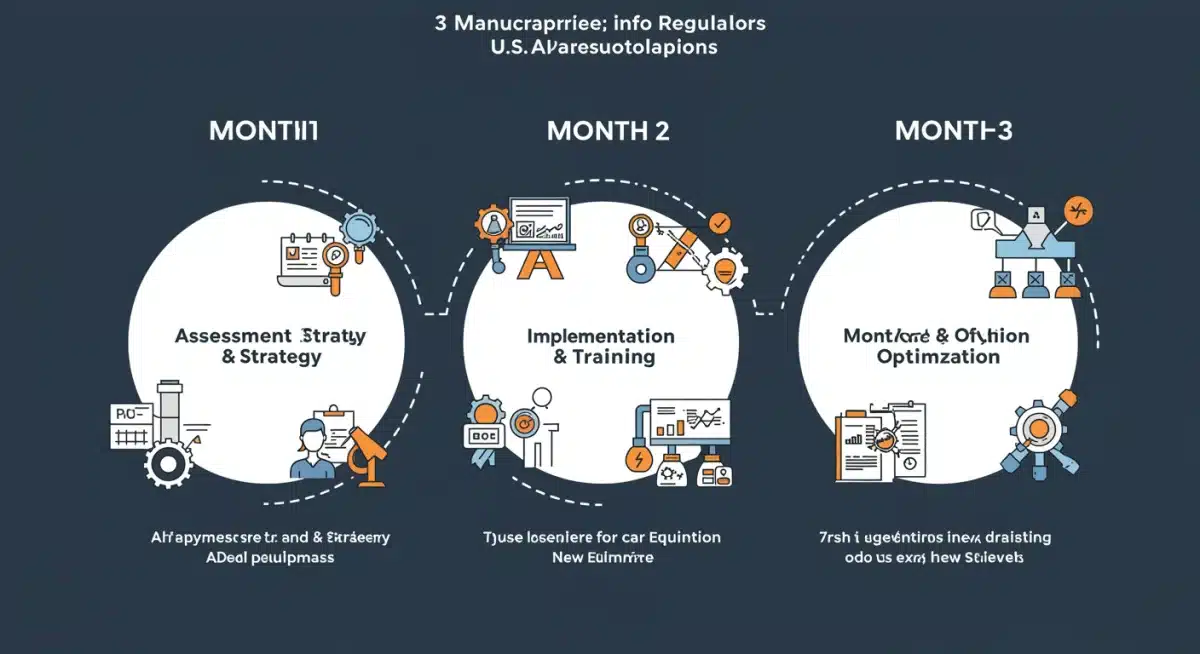

Month 1: Assessment and Strategic Planning

The initial month of this 3-month action plan is crucial for laying a solid foundation. Manufacturers must conduct a thorough internal assessment to understand their current environmental footprint and identify areas where they fall short of the new EPA standards. This involves a detailed audit of existing processes, technologies, and compliance protocols.

Developing a comprehensive strategy based on this assessment is the next vital step. This strategy should outline specific goals, allocate resources, and establish a clear timeline for implementation. Engaging key stakeholders, including legal, engineering, and production teams, is essential to ensure a holistic and integrated approach to compliance.

Conducting an Environmental Audit

An effective environmental audit should cover all aspects of a manufacturer’s operations, from raw material sourcing to product delivery. This includes evaluating energy consumption, waste generation, water usage, and emissions. Specialized consultants can provide valuable expertise in performing these audits, ensuring accuracy and identifying potential risks and opportunities.

- Energy Consumption Analysis: Identify inefficiencies and opportunities for renewable energy integration.

- Waste Stream Mapping: Categorize and quantify waste to pinpoint reduction and recycling opportunities.

- Compliance Gap Analysis: Compare current practices against new EPA regulations to identify discrepancies.

Month 2: Technology Integration and Employee Training

With a clear strategy in place, the second month focuses on the practical implementation of green technologies and comprehensive employee training. This phase is critical for translating strategic plans into tangible operational changes that meet EPA requirements. Manufacturers should prioritize technologies that offer both environmental benefits and operational efficiencies.

Investing in new equipment or upgrading existing machinery to incorporate greener alternatives is often necessary. This could range from energy-efficient HVAC systems and LED lighting to advanced waste treatment facilities and cleaner production processes. Simultaneously, a robust training program will ensure that all employees understand their roles in maintaining compliance and operating new systems effectively.

Implementing Green Technologies

The selection and implementation of green technologies should be guided by both the audit findings and the strategic plan. Manufacturers should seek solutions that not only comply with regulations but also offer long-term cost savings and enhance their brand image. This might involve adopting automation to reduce material waste, switching to lower-impact solvents, or installing advanced filtration systems.

Consideration should also be given to the integration of digital tools for environmental monitoring and data collection. These systems can provide real-time insights into performance, allowing for immediate adjustments and continuous improvement. The upfront investment in these technologies can yield significant returns in terms of efficiency, compliance, and reduced operational risk.

Month 3: Monitoring, Reporting, and Continuous Improvement

The final month of this initial action plan is dedicated to establishing robust monitoring systems, refining reporting procedures, and embedding a culture of continuous improvement. Compliance is an ongoing process, and manufacturers must be equipped to track their performance, report accurately, and adapt to future regulatory changes.

Developing a comprehensive monitoring framework will involve setting up key performance indicators (KPIs) related to environmental impact. Regular audits and reviews will ensure that the green technologies are functioning as intended and that employees are adhering to new protocols. This proactive approach will help manufacturers stay ahead of potential issues and demonstrate their commitment to sustainability.

Establishing Robust Reporting Protocols

Accurate and timely reporting to the EPA is non-negotiable. Manufacturers should standardize their data collection and reporting processes, utilizing software solutions where possible to streamline submissions. This includes maintaining meticulous records of emissions, waste disposal, and resource consumption. Transparency in reporting builds trust with regulatory bodies and the public.

- Automated Data Collection: Implement systems for real-time environmental data gathering.

- Regular Internal Audits: Conduct monthly checks to ensure adherence to new procedures.

- Stakeholder Communication: Keep all relevant teams informed of progress and any emerging challenges.

- Documentation Management: Centralize and organize all compliance-related documents for easy access.

Leveraging Incentives and Funding Opportunities

Beyond compliance, U.S. manufacturers have the opportunity to leverage various incentives and funding programs designed to support green technology adoption. The federal government, along with many state and local authorities, offers grants, tax credits, and loan programs to businesses investing in sustainable practices. Identifying and applying for these opportunities can significantly offset the costs associated with upgrading to greener operations.

Exploring these financial aids is a critical component of a comprehensive green tech strategy. These incentives are often aimed at promoting innovation in areas such as renewable energy, energy efficiency, waste reduction, and the development of sustainable materials. Manufacturers should proactively research available programs and assess their eligibility, as these can provide a substantial competitive advantage.

Federal and State Programs

Several key programs are currently active. The Department of Energy (DOE) offers various grants for energy efficiency and renewable energy projects. The EPA itself has programs supporting pollution prevention and sustainable materials management. State-level incentives often include tax abatements for green building initiatives or subsidies for installing solar panels.

For example, the Investment Tax Credit (ITC) for solar and wind energy can significantly reduce the net cost of installing renewable energy systems. Similarly, various state-specific programs might offer rebates for purchasing energy-efficient manufacturing equipment. Manufacturers should consult with financial advisors specializing in environmental incentives to maximize their benefits.

The Competitive Advantage of Green Manufacturing

Adopting green technologies and complying with EPA regulations offers more than just legal adherence; it presents a significant competitive advantage. Manufacturers who proactively embrace sustainability often see improved brand reputation, increased operational efficiency, and enhanced market access. Consumers and business partners increasingly prioritize environmentally responsible companies.

A commitment to green manufacturing can also lead to innovation. The drive to reduce waste or energy consumption often sparks new ideas for product design, process optimization, and supply chain management. This innovation can result in proprietary technologies, patented processes, and a stronger position in the marketplace, attracting both talent and investment.

Market Demand and Brand Reputation

Studies consistently show a growing consumer preference for sustainable products and brands. By demonstrating a strong commitment to environmental stewardship, manufacturers can differentiate themselves in a crowded market. This enhanced brand reputation can lead to increased sales, customer loyalty, and a stronger competitive edge.

- Customer Preference: Attract environmentally conscious consumers and businesses.

- Investor Interest: Appeal to ESG (Environmental, Social, Governance) focused investors.

- Supply Chain Resilience: Build stronger, more sustainable supply chain relationships.

- Talent Attraction: Attract and retain skilled employees who value corporate social responsibility.

| Key Action | Brief Description |

|---|---|

| Month 1: Assessment | Conduct a comprehensive environmental audit and develop a strategic compliance plan. |

| Month 2: Implementation | Integrate green technologies and provide thorough employee training. |

| Month 3: Monitoring | Establish robust monitoring, reporting, and continuous improvement protocols. |

| Incentives & Advantage | Leverage funding opportunities and recognize competitive benefits of green manufacturing. |

Frequently Asked Questions About EPA Green Tech Regulations

The primary goals are to significantly reduce industrial carbon footprints, enhance waste management practices, and promote the widespread adoption of sustainable production processes across U.S. manufacturing sectors. These regulations aim for measurable environmental improvements.

While specific deadlines vary by regulation, the overarching expectation is for rapid adaptation. A proactive 3-month action plan is recommended for initial assessment, technology integration, and establishing monitoring systems to ensure timely compliance.

Manufacturers can access various federal and state programs, including grants, tax credits, and low-interest loans. These incentives aim to offset the costs of investing in renewable energy, energy-efficient equipment, and pollution prevention technologies.

Employee training is crucial for successful implementation. It ensures that staff understand new operational procedures, safely operate green technologies, and adhere to compliance protocols, thereby minimizing risks and maximizing efficiency.

Adopting green practices enhances brand reputation, improves operational efficiency, and expands market access. It also fosters innovation, attracts top talent, and can lead to significant long-term cost savings and competitive differentiation.

What Happens Next

The landscape for U.S. manufacturers is irrevocably shifting towards greater environmental accountability. As these new EPA regulations solidify, the focus will move from initial compliance to sustained performance and continuous innovation. Expect to see increased scrutiny on reported data and further incentives for those who exceed minimum requirements. Manufacturers who embrace this transition proactively will not only avoid penalties but also position themselves as leaders in a green economy. The coming months will reveal which companies are truly committed to sustainability and reap the long-term benefits of a forward-thinking approach.