Green Manufacturing: Boosting U.S. Production Efficiency 12% by 2025

Breaking news reveals that The Latest in Green Manufacturing: Boosting U.S. Production Efficiency by 12% While Cutting Waste in 2025 is not just an ambitious goal but a tangible reality for American industry. New reports indicate a concerted national effort, driven by technological advancements and policy shifts, is rapidly transforming the manufacturing landscape. This initiative promises significant economic and environmental benefits, positioning the U.S. as a leader in sustainable industrial practices.

The Drive Towards Sustainable Production

The push for sustainable production in the United States has gained unprecedented momentum, with industry leaders and government agencies aligning on aggressive targets for efficiency and waste reduction. This collective effort is not merely about environmental stewardship; it’s a strategic move to enhance competitiveness, reduce operational costs, and build resilience in supply chains. As of recent announcements, a 12% boost in production efficiency by 2025 is now considered achievable, alongside substantial cuts in manufacturing waste.

This ambitious goal is underpinned by a confluence of factors, including rapid innovation in clean technologies, increased investment in automation, and a growing consumer demand for ethically produced goods. Companies are realizing that integrating green practices is no longer an optional add-on but a fundamental component of future success. The benefits extend beyond the bottom line, fostering a positive brand image and attracting a skilled workforce.

Policy and Investment Catalysts

Recent legislative actions and significant private sector investments are acting as powerful catalysts for this green transformation. Government incentives, tax credits, and grants are making it more financially viable for manufacturers to adopt sustainable technologies and processes. These policies are designed to de-risk the transition and accelerate the adoption of cutting-edge solutions across various industrial sectors.

- Tax Credits for Green Tech: New federal tax credits are encouraging the purchase and installation of energy-efficient machinery and renewable energy systems.

- Research and Development Funding: Increased government funding is being directed towards R&D in areas like advanced materials, circular economy models, and industrial symbiosis.

- Private Sector Commitments: Major corporations are pledging billions towards decarbonization efforts within their supply chains and manufacturing operations.

- Workforce Development Programs: Initiatives to train and upskill workers in green manufacturing techniques are essential to meet the growing demand for specialized labor.

Technological Innovations Fueling Efficiency

At the heart of the projected 12% efficiency gain are groundbreaking technological innovations that are redefining manufacturing processes. From advanced robotics to artificial intelligence and the Internet of Things (IoT), these technologies are enabling manufacturers to optimize resource utilization, minimize downtime, and improve product quality with unprecedented precision. The integration of these tools allows for real-time monitoring and adaptive control, leading to significant operational improvements.

Digital twins, for example, are creating virtual replicas of physical production lines, allowing engineers to simulate and optimize processes without disrupting actual operations. This predictive capability helps identify bottlenecks, test new configurations, and fine-tune parameters for maximum efficiency and minimal waste. The adoption of these sophisticated tools is becoming widespread, particularly in high-value manufacturing sectors.

Automation and Smart Manufacturing

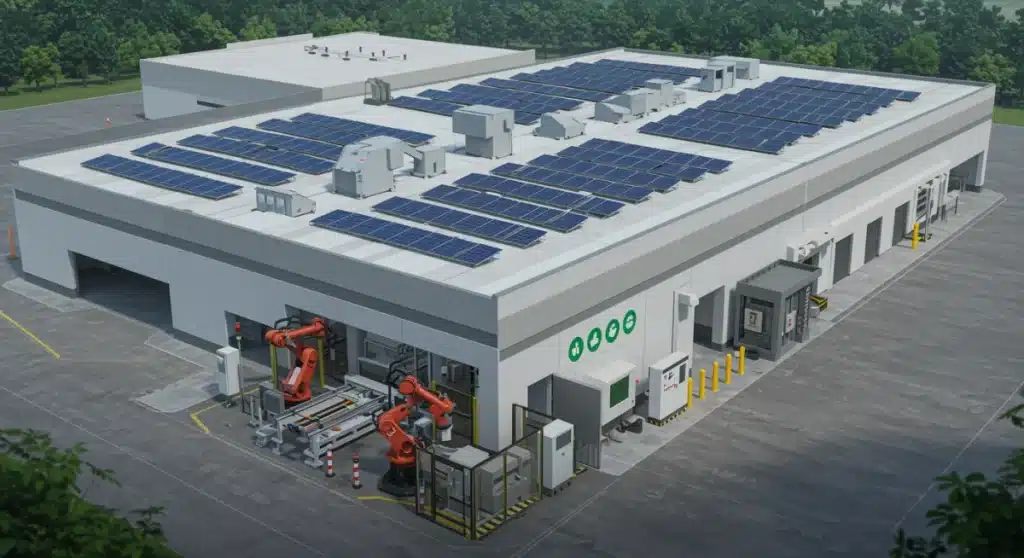

Automation plays a crucial role in enhancing efficiency and consistency. Collaborative robots (cobots) are working alongside human employees, taking on repetitive or hazardous tasks, thereby increasing productivity and improving workplace safety. Smart factories, powered by IoT sensors and AI algorithms, are becoming the norm, enabling machines to communicate with each other and make autonomous adjustments.

The data generated by these interconnected systems provides invaluable insights into energy consumption, material flow, and waste generation. This data-driven approach allows manufacturers to identify areas for improvement, implement targeted interventions, and continuously refine their processes. The result is a leaner, more agile, and significantly more efficient manufacturing ecosystem.

Waste Reduction Strategies and Circular Economy

Cutting waste is a cornerstone of the green manufacturing movement, with ambitious targets set for 2025. This involves not only reducing waste generation at the source but also rethinking the entire product lifecycle through circular economy principles. Manufacturers are increasingly adopting strategies that emphasize reuse, repair, refurbishment, and recycling, moving away from the traditional linear ‘take-make-dispose’ model.

New material science advancements are also contributing significantly to waste reduction. The development of biodegradable materials, recyclable composites, and more durable components is reducing the environmental footprint of products and processes. Companies are also exploring industrial symbiosis, where waste from one process becomes a valuable input for another, creating closed-loop systems that minimize landfill dependency.

Advanced Recycling and Material Recovery

Investment in advanced recycling technologies is critical for achieving significant waste reduction. Innovations in chemical recycling, for instance, are enabling the recovery of raw materials from complex waste streams that were previously unrecyclable. This not only diverts waste from landfills but also reduces the demand for virgin resources, leading to a more sustainable supply chain.

- Chemical Recycling: Breaking down plastics into their molecular components for reuse in new products.

- Urban Mining: Recovering valuable materials from discarded electronic devices and other end-of-life products.

- Industrial Symbiosis Networks: Creating regional networks where industrial byproducts are exchanged and utilized.

- Product-as-a-Service Models: Shifting ownership to manufacturers who are responsible for product end-of-life, encouraging design for durability and recyclability.

Energy Efficiency and Renewable Integration

A significant aspect of green manufacturing involves optimizing energy consumption and transitioning to renewable energy sources. Manufacturers are implementing sophisticated energy management systems that monitor and control energy use across their facilities, identifying opportunities for savings. This includes upgrading to high-efficiency machinery, optimizing heating, ventilation, and air conditioning (HVAC) systems, and improving insulation.

The integration of renewable energy, such as solar, wind, and geothermal power, is also accelerating. Many factories are installing on-site renewable energy generation capabilities, reducing their reliance on fossil fuels and lowering their carbon footprint. Power purchase agreements (PPAs) with renewable energy providers are also becoming common, allowing companies to source clean energy without the upfront investment in infrastructure.

Smart Grids and Energy Storage

The adoption of smart grid technologies and advanced energy storage solutions is further enhancing energy efficiency. Smart grids allow for better management of energy supply and demand, integrating intermittent renewable sources more effectively. Battery storage systems are enabling manufacturers to store excess renewable energy for use during peak demand periods or when renewable generation is low, ensuring a consistent and sustainable power supply.

This holistic approach to energy management not only reduces operational costs but also contributes to greater energy security and a more stable grid. The shift towards cleaner energy sources is a direct response to global climate goals and a growing recognition of the long-term economic benefits associated with reduced emissions.

Supply Chain Sustainability and Transparency

Achieving a 12% boost in efficiency and significant waste reduction by 2025 requires a comprehensive approach that extends beyond the factory floor to encompass the entire supply chain. Manufacturers are increasingly scrutinizing their suppliers’ environmental practices, demanding greater transparency and adherence to sustainability standards. This includes evaluating the carbon footprint of transportation, the ethical sourcing of raw materials, and the waste management practices of upstream partners.

Blockchain technology is emerging as a powerful tool for enhancing supply chain transparency, allowing companies to track products from their origin to the end consumer. This level of traceability helps identify and mitigate environmental risks, ensures compliance with sustainability certifications, and builds consumer trust. Collaborations across the supply chain are essential for fostering a truly green manufacturing ecosystem.

Ethical Sourcing and Logistics Optimization

Ethical sourcing practices are becoming non-negotiable, with companies prioritizing suppliers who demonstrate strong environmental and social responsibility. This includes avoiding materials from regions with poor environmental records or human rights abuses. Logistics optimization, through routes, modes of transport, and packaging, is also crucial for reducing emissions and waste associated with product distribution.

The focus on sustainable supply chains is driven by both regulatory pressures and consumer expectations. Companies that fail to address these issues risk reputational damage and market share loss. Conversely, those that embrace supply chain sustainability gain a competitive advantage and contribute to a more resilient and responsible global economy.

Economic and Environmental Impact Projections

The projected 12% increase in U.S. production efficiency coupled with substantial waste reductions by 2025 is expected to yield significant economic and environmental benefits. Economically, this translates to lower operational costs, increased profitability, and enhanced global competitiveness for American manufacturers. The creation of new green jobs, particularly in technology development, installation, and maintenance, is also a key outcome.

Environmentally, the impact is equally profound. Reduced energy consumption means fewer greenhouse gas emissions, contributing to climate change mitigation efforts. Waste reduction minimizes landfill burden and pollution, preserving natural resources. The shift towards a circular economy model fosters a more sustainable relationship between industry and the environment, ensuring long-term ecological health.

Long-Term Vision for U.S. Industry

This initiative represents a pivotal moment for U.S. manufacturing, signaling a long-term commitment to sustainability and innovation. The investment in green technologies and practices today is laying the groundwork for a future where economic prosperity and environmental protection go hand-in-hand. The lessons learned and technologies developed over the next few years will set new benchmarks for industrial excellence worldwide, reinforcing the U.S.’s leadership in the global economy.

The focus on localized production, enabled by advanced manufacturing techniques, also enhances national security and reduces dependence on volatile international supply chains. This strategic realignment ensures that the U.S. industrial base remains robust, innovative, and environmentally responsible for generations to come. The 2025 targets are just the beginning of a broader transformation.

| Key Aspect | Brief Description |

|---|---|

| Efficiency Target | U.S. production efficiency projected to increase by 12% by 2025. |

| Waste Reduction | Significant cuts in manufacturing waste are a core objective. |

| Key Technologies | Advanced robotics, AI, IoT, and digital twins drive optimization. |

| Economic Impact | Lower costs, increased competitiveness, and new green job creation. |

Frequently Asked Questions About Green Manufacturing

Green manufacturing involves processes that minimize negative environmental impacts, conserve natural resources, and provide safe workplaces. It focuses on reducing waste, pollution, and energy consumption throughout the product lifecycle, from design to disposal.

This increase is projected through the widespread adoption of advanced technologies like AI, IoT, robotics, and digital twins, coupled with optimized energy management and circular economy principles. Government incentives and private investments are accelerating these changes across industries.

Waste reduction is crucial, encompassing strategies from minimizing material usage to implementing advanced recycling and industrial symbiosis. It aims to transform waste into valuable resources, significantly reducing landfill impact and resource depletion, central to the circular economy.

Manufacturers benefit from reduced operational costs due to lower energy and material consumption, increased competitiveness in global markets, and enhanced brand reputation. It also fosters innovation and creates new job opportunities in sustainable technologies and practices.

Supply chains are integrating sustainability through ethical sourcing, logistics optimization, and increased transparency using technologies like blockchain. Manufacturers are demanding greener practices from suppliers to ensure environmental and social responsibility across their entire value chain.

Looking Ahead

The push for The Latest in Green Manufacturing: Boosting U.S. Production Efficiency by 12% While Cutting Waste in 2025 signals a profound shift in American industry. What began as an environmental imperative has evolved into a strategic economic advantage. As 2025 approaches, observers will be closely watching for granular data on efficiency gains and waste metrics, which are expected to validate these aggressive targets. Further policy developments and private sector commitments are anticipated, likely expanding the scope of green initiatives. This trajectory points towards a more resilient, competitive, and environmentally responsible manufacturing future for the United States, setting a global benchmark for sustainable industrial growth.